Finite element analysis and computational fluid dynamics often form a key part of the design process.

We collaborate with project consultant teams to devise and carry out full-scale testing to validate this analysis, typically on a worst-case scenario.

Trials can include, for example, simulating millions of trains passes; accelerated durability testing to represent up 120 years life.

Testing is closely monitored. Measurement instrumentation includes:

- Strain gauges

- Accelerometers

- Thermocouples

- Flowmeters

- Displacement transducers

- Load cells

Measurements are recorded by data loggers (up to 150 channels) and can gather over two billion bits of information.

Recent projects

- Crossrail/Elizabeth Line - Testing of trackside equipment

- HS2 – Fatigue testing of noise barriers

- Cross-passage Safety Doors – Mirroring forces on the doors incurred by train passes

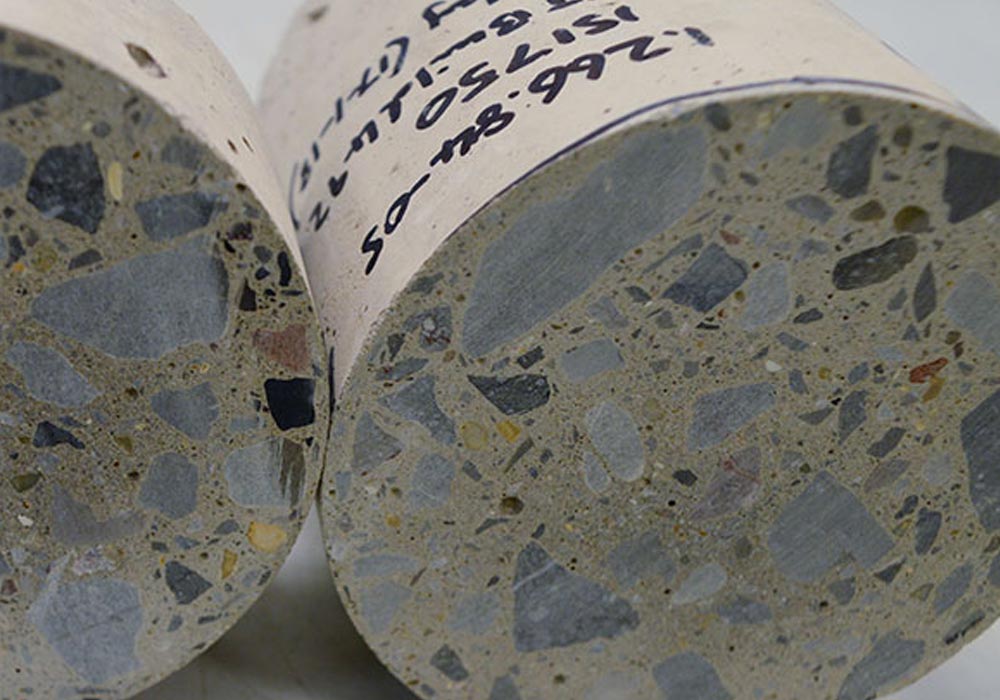

Construction of 10m tunnel for accelerated durability testing of trackside equipment

Station roof model, final testing simulated a one in 540-year event.